We deliver to lockers!

We deliver to lockers!

Pick up your orders anytime, hassle-free!

Fast Delivery!

Fast Delivery!

Orders placed by 2:00 PM are shipped the same day. Delivered within 24h!

2-Year Warranty

2-Year Warranty

Reliable products, worry-free!

Easy 14-Day Returns

Easy 14-Day Returns

Unused items? No questions asked!

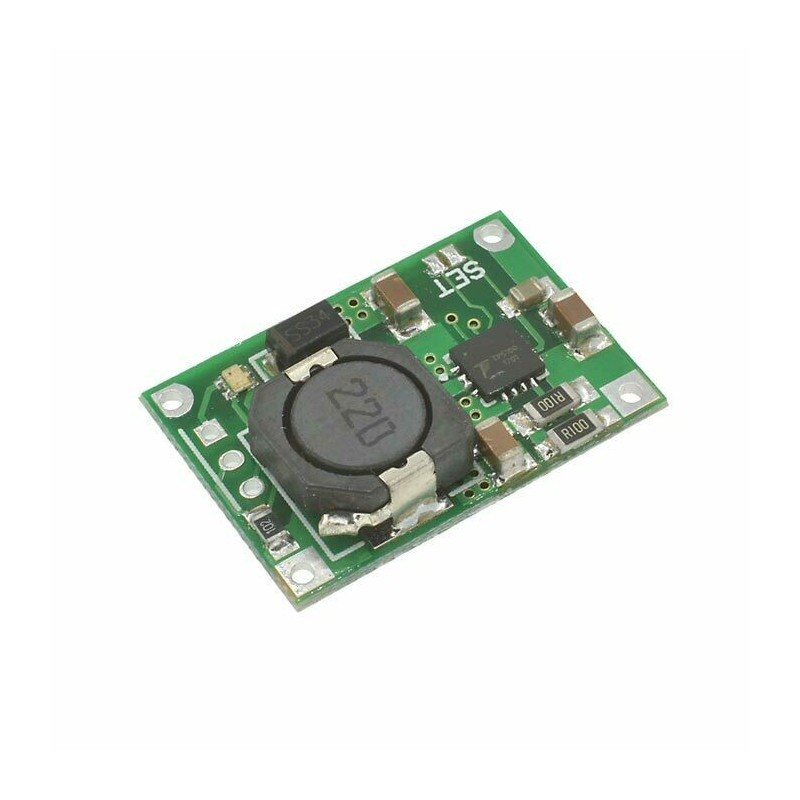

This charging module is for lithium batteries composed of one or two 3.7V cells.

For use with a single cell:

For use with two cells:

The charging current can be adjusted using the two SMD resistors "R100" on the board.

If one of the resistors is removed, the charging current is 1A.

When both resistors are present, the charging current is 2A.

Lithium battery technology is DANGEROUS and creating a battery requires a very good understanding of the field.

An improperly made battery, both electrically and mechanically/thermally, can catch fire or even explode randomly.

Many economic operators refuse to transport lithium batteries because of these dangers.

It is STRICTLY FORBIDDEN to use cells with different internal resistances (unchecked, recovered, low quality, with different wear levels, etc.)! The capacity and internal resistance of the cells must be as close as possible!

Otherwise, the battery's lifespan will be drastically reduced or the battery may be violently destroyed when put into operation.

The capacity/internal resistance of batteries is measured using special battery testing devices.

Ideally, use cells from the same supplier, the same lot, and tested to have similar internal resistance.

Using unsuitable cells leads to their failure, the failure of other cells, and the loss of warranty.

Due to different internal resistances, one cell will discharge faster than another, and the voltage will drop below its minimum voltage, leading to irreversible damage.

A damaged cell will then lead to the chain destruction of other cells and the BMS module.

The cells must be connected using spot welding and not soldered.

The conductors used to connect the cells must be dimensioned to support the maximum current generated by all the battery cells.

When assembling the battery, consider that all cells are permanently under voltage. An accidental short circuit can lead to electrocution, destruction of cells and the BMS with the aforementioned consequences.

The battery must be protected against impacts, punctures, and external electrical contacts.

It is recommended to completely isolate the battery and use a metal case to protect against a possible fire.

The cables require crimped terminals/connectors using specialized tools or soldered connectors.

The module needs adequate cooling depending on the current intensity used. If cooling is not adequately provided, they will fail, resulting in the loss of warranty.

Cooling may require the attachment of a heatsink (not included) and ensuring proper airflow: the case should be ventilated, or a fan should be used (not included).

The information presented above is basic and by no means sufficient. It does not substitute for in-depth studies in the field.

The modules are intended exclusively for specialized and authorized firms in the field, and not for amateurs.

Maximum charging current: 2A

Input voltage: 5V-15V (single cell) or 9V-15V (two cells) DC

1x Lithium battery charging module TP5100

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent

Reference: CSPDGR_MP001636

Brand: Raspberry Pi

check_circle

check_circle