Cart 0 Product Products (empty)

No products

To be determined Shipping

0,00 lei Tax

0,00 lei Total

Prices are tax included

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products (tax incl.)

Total shipping (tax incl.) To be determined

Tax 0,00 lei

Total (tax incl.)

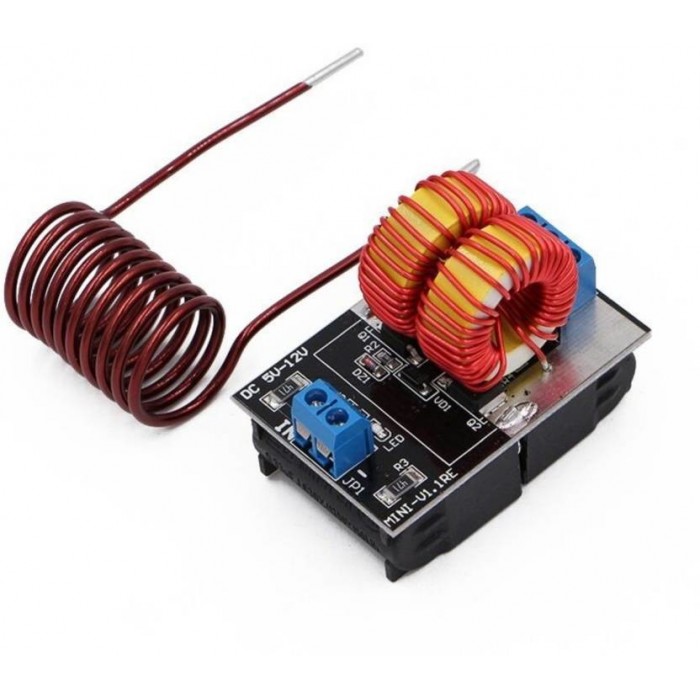

DC 5-12V ZVS Low Voltage Induction Heating Power Supply Module

View larger

View larger HOHFPZ_MODULE_HEAT

New product

25 Items

Description:

Input voltage: 5v-12v

Module dimensions:5.5*4*2 cm(L*W*H)

Product Weight: 119g

Coil size: length:7.5cm

width: 2.8cm

ZVS heating power supply module including heating coil

Input voltage DC5V-12V(We are not guarantee the module will work when the voltage is over 12V or less than 5V)

Maximum power 120W(when 12V eddy-current heating)

Ensure all the components welding right,power line connect in right way,than to set up an electric circuit.

The width of the heated object is as far as possible between the 1/3~1/2 of the inner diameter of the heating coil, the maximum not more than 2/3!

When using battery and battery power supply, it must be ensured that the working voltage is above 4.5V! Do not ensure that the voltage is always above 4.5V during operation, do not use battery or battery power supply! Do not use dry battery power!

The width of the heated object should be between 1/3 and 1/2 of the inner diameter of the heating coil, and the maximum should not exceed 2/3!

The diameter of the heated object should be controlled within 20mm as much as possible. If the heating is too large, it will be difficult to heat up to red. After all, the power is limited.

Inductive heating, usually work for 5 minutes to power off cooling. Because the current is relatively large during induction heating, the coil heat is also relatively large. When heated, part of the heat generated by the heated object is transmitted to the heating coil. For a long time, the temperature of the heating coil is high. If the heating coil is connected to the terminal, the plastic part of the terminal will be melted! Therefore, it is best to solder the heating coil directly to the PCB during induction heating.

For long-term use, it is recommended to use a copper tube as a coil and cool it with water.

Blue LED power indicator, there is no electricity, you can see if the light is off!

No customer reviews for the moment.